DM Cup Maintenance & Spare Parts

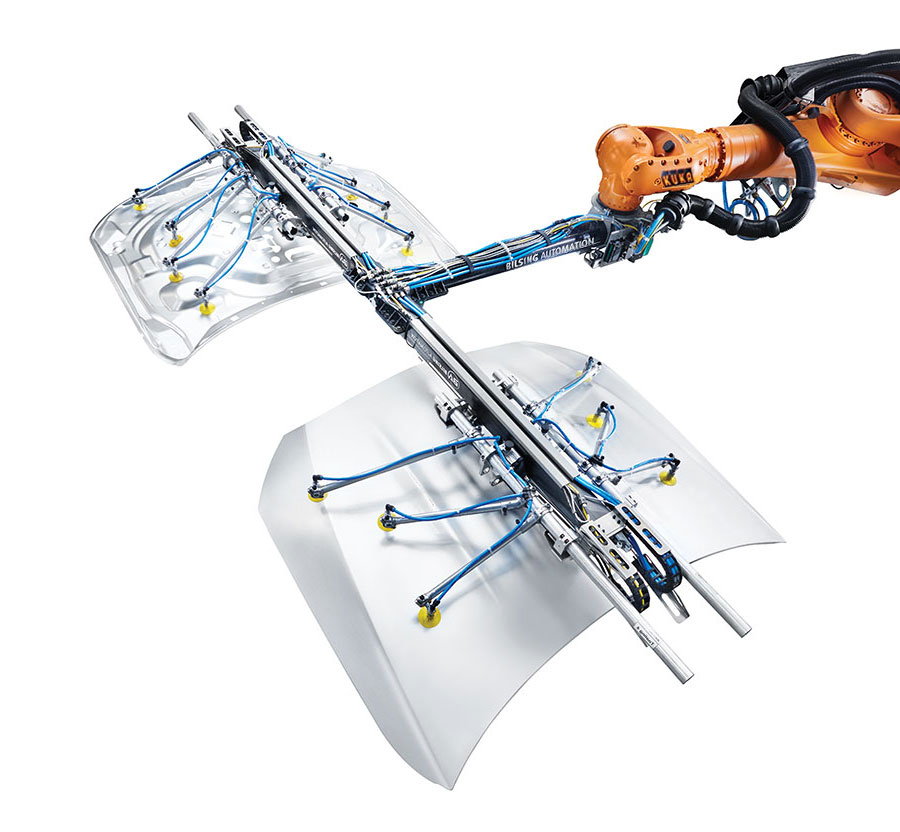

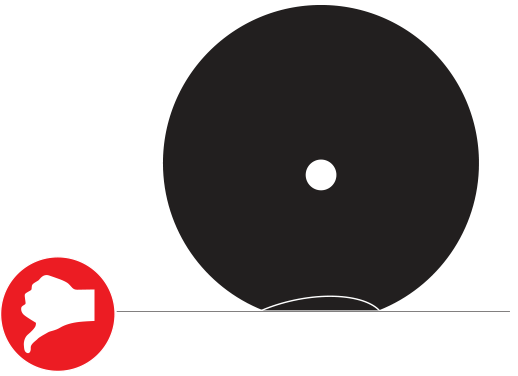

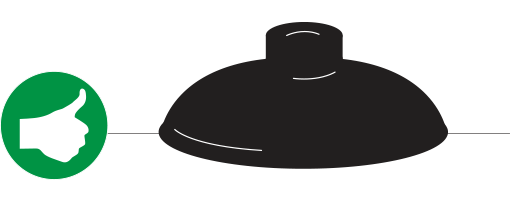

Proper care and storage of your vacuum cups can dramatically improve their performance and life. If you have questions regarding how to best care for, maintain and store your cups, please reach out to your local Bilsing Automation representative to discuss your unique needs.

English

English Deutsch

Deutsch