Bilsing Automation offers a wide variety of vacuum generating products to meet an array of applications.

We offer a wide variety of vacuum cups. Our cups come in an array of shapes, materials, hardness, and industry mounts to meet a vast array of applications. Whether you need a solution that can handle transverse forces found in the stamping industry, hot forming vacuum cups that can withstand extreme temperatures, or cups that nicely follow complex contoured parts, we have a solution for you.

Applications:

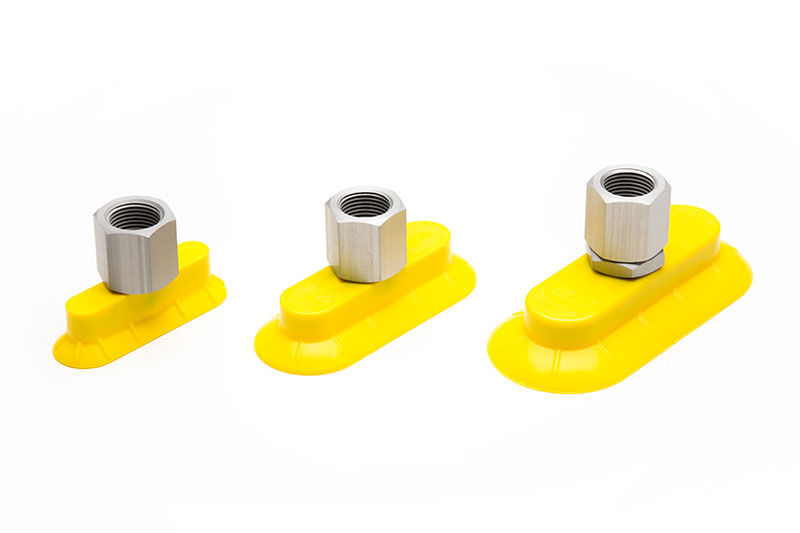

Perfect for flat, convex surfaces, edges, and limited dimensional geometries. Handles aluminum and steel panels as well as outer surface panels with solid lubricant and oils. Optimal for panel loader and plastics handling up to 100 degrees. Combines holding forces of flat foot cups with the advantages of traction cups—increased SPM

compared to PF Series.

Characteristics:

Extremely wear resistant material TPU. Interior rib geometry provides very high adhesion and resisting transverse forces. Does not cause surface damage on thin panels.

Durometer: Shore 80 (yellow)

Applications:

Perfect for flat, convex surfaces, edges, and limited dimensional geometries. Handles aluminum and steel panels as well as outer surface panels with solid lubricant and oils. Optimal for panel loader and plastics handling up to 100 degrees.

Characteristics:

Extremely wear resistant material TPU. Interior rib geometry provides very high adhesion and resisting transverse forces. Does not cause surface damage on thin panels.

Durometer: Shore 80 (yellow)

Applications:

Perfect for flat or slightly curved parts. Aluminum and vinyl acetate films or other material with sensitive Class-A automotive panel surfaces. Suitable for securing and transporting oily wet parts.

Characteristics:

The interior rib geometry holds parts securely during the accelerated or decelerated transfer while avoiding the pulling of dents.

Durometer: Shore 45 (red) and 55 (yellow)

Applications:

Perfect for flat or slightly curved parts. Aluminum and vinyl acetate films or other material with sensitive Class-A automotive panel surfaces. Suitable for securing and transporting oily wet parts.

Characteristics:

The interior rib geometry holds parts securely during the accelerated or decelerated transfer while avoiding the pulling of dents.

Durometer: Shore 45 (red) and 55 (yellow)

Applications:

Excellent for destacking, prebend tools, machine feeders, stacker and other linear or multi-axis automation. Safe transport of the parts at high transportation speed. Soiled and oily surfaces. Wood, paper board containers, plastics, glass.

Characteristics:

The shape of the cup accommodates uneven or pre-formed parts panels. The interior rib geometry holds parts securely during the accelerated or decelerated transfer while avoiding the pulling of dents.

Durometer: Shore 45 (red) and 55 (yellow)

Applications:

General light-duty operating conditions for parts with polished or painted surfaces. Oval shape is provides excellent suctions power at small widths of parts.

Characteristics:

Due to its flexible design the contact surface of the cup will accommodate parts with uneven surfaces and considerable contour. It’s flexible even under conditions of high acceleration, deceleration, and rotations at high speed. Its soft seal allows it to manage polished and painted surfaces without damaging their sensitive surfaces.

Durometer: Shore 45 (red) and 55 (yellow)

Applications:

General light-duty operating conditions. erratically formed parts with polished or painted surfaces. Well suited for wood, paper board containers, plastics, glass.

Characteristics:

Due to its flexible design the contact surface of the cup will accommodate parts with uneven surfaces and considerable contour. It’s flexible even under conditions of high acceleration, deceleration, and rotations at high speed. Its soft seal allows it to manage polished and painted surfaces without damaging their sensitive surfaces.

Durometer: Shore 45 (red) and 55 (yellow)

Applications:

Excellent for destacking tubular parts, or in the load/unload of hydroforming applications.

Characteristics:

The angular shape and soft edge of the cup is pliant and easily conforms to many structures. This cup is used in applications where an exact transport and deposit of the part in a repeatable position is essential. The interior rib geometry holds parts securely during the accelerated or decelerated transfer while avoiding the pulling of dents.

Durometer: Shore 45 (red) and 55 (yellow)

Applications:

These cups area available in popular Bilsing shapes and sizes. The black NBR material is designed to work in temperatures up to +250° C.

Characteristics:

These cups share the same characteristics of their PF, HT, DM and BT Series counterparts with the benefits of working in hot forming applications where direct contact with a heated part is required.

Durometer: Shore 70 (black)

Provide us with your name and email address to download our Quality Certificates.

Provide us with your name and email address to download our ISO 14001:2015 Certificate.

Provide us with your name and email address to download our PFG Series Vacuum Cup Brochure.

Provide us with your name and email address to download our Servo T-Beam Brochure.

Provide us with your name and email address to download our Vacuum Cup Brochure.

Provide us with your name and email address to download our Carbon Fiber Tech Brochure.

Provide us with your name and email address to download our Carbon Fiber Brochure.

Provide us with your name and email address to download our Modular System Components Brochure.

Provide us with your name and email address to download our Klemmgreifer Grippers Brochure.

Provide us with your name and email address to download our Tooling System Flyer.

Provide us with your name and email address to download our Complete Components Product & Applications Details Catalog.

Provide us with your name and email address to download our Plastics Part Manufacturing Components Catalog.

Provide us with your name and email address to download our Press Shop, Hot Forming & Body Shop Components Catalog.